Lockout / Tagout Safety Training

The Occupational Safety and Health Administration (OSHA) standard for "The Control of Hazardous Energy (Lockout / Tagout), Title 29 Code of Federal Regulations (CFR) Part 1910.147 & 1910.133" address both the practices and procedures for disabling or de-energizing equipment or machinery and the requirements for protecting employees who work on electrical circuits and equipment.

According to OSHA, Lockout / Tagout violations are some of the "Most Frequently Cited Standards". In 2018 - 2019 they ranked #4.

Current Industry estimates show that compliance with these standards prevents approximately 120 fatalities and 50,000 injuries every year.

Many of these incidents and injuries could be avoided simply by understanding and implementing a proper Lockout / Tagout on the equipment prior to the commencement of any work where a person could be exposed to an electrical hazard.

There are many other types of stored energy that could be present in the workplace that could pose a serious hazard to employees such as:

- Hydraulic

- Mechanical

- Pnuematic

- Chemical

- Thermal

We understand the importance of having effective safety training protocols in place for your team and recognize the difference it makes when an employee has gained the skills necessary to apply what they have learned in the field.

Since not all tasks or activities are the same, the training measures that are implemented shouldn't be either, they should be specific to the level of experience, assigned tasks, and responsibility of your employees.

We offer several levels of Lockout / Tagout training to accommodate your current needs:

Level I - Affected Personnel

Level II - Authorized Personnel

Level III - Management & Supervision

Here are just a few of the topics that are covered in our Lockout / Tagout courses:

- OSHA / NFPA 70E Requirements

- Safety-Related Work Practices

- Specific Types of Hazards

- Hazard Mitigation Techniques

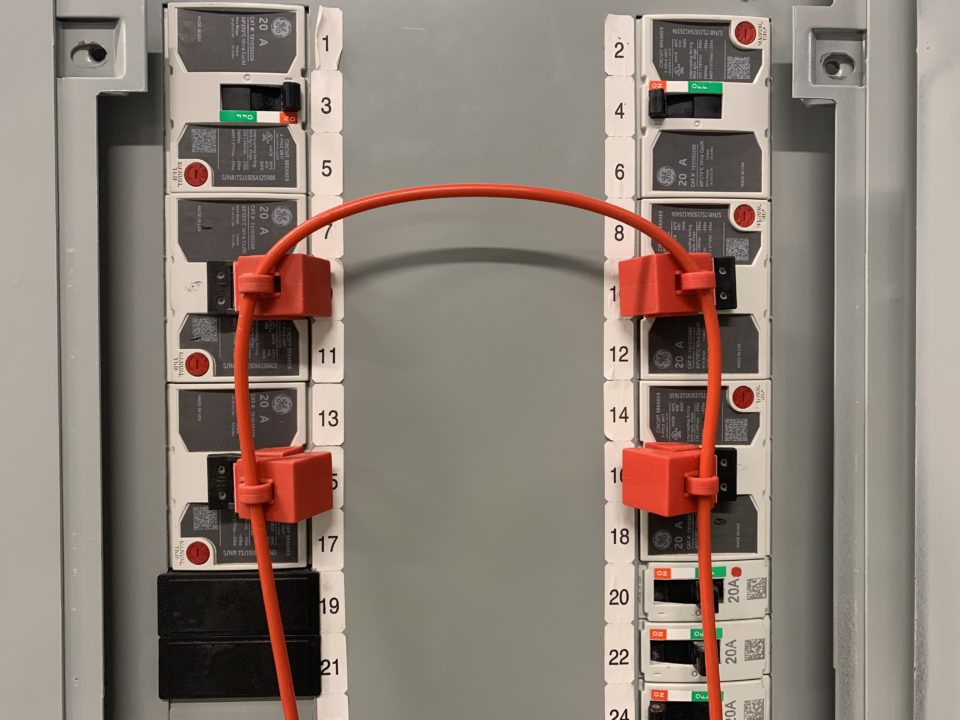

- Lockout / Tagout Devices

- Electrically Safe Work Condition (ESWC)

- Roles & Responsibilities

- Lockout / Tagout Program Requirements

- Types of Lockout / Tagout

- Equipment Maintenance Requirements

- Special Equipment / Stored Energy

- Documentation & Auditing

Our course instructors are licensed industry professionals with decades of experience in the electrical field and have an in-depth, firsthand working knowledge of the proven best practices required to keep you and your team safe.

Our goal is that each person who may be exposed to an electrical hazard have an in-depth understanding of how to safely establish a proper Lockout / Tagout.

Connect with one of our Electrical Safety Specialist today to find out more about our comprehensive virtual and on-site training options.